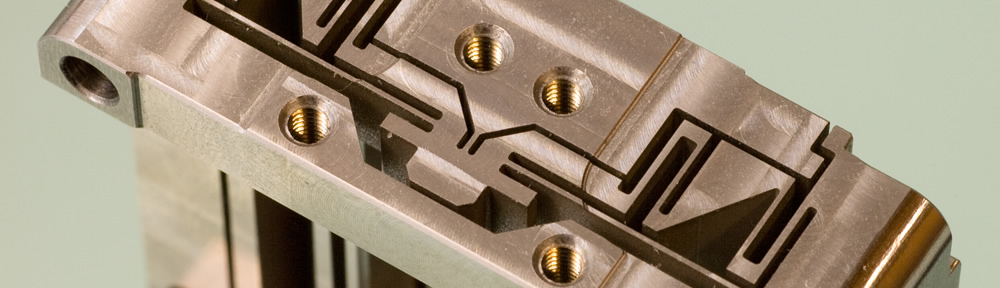

Final assembly

Our assembly department completes the offerings range from GEWO. From the initial design to final assembly, and at the request dispatch packaged product, all under one roof – and thus faster, more economically and quality.

The proper integration of electric and pneumatic units, wiring and installation of motors and sensors are part of the standard repertoire.

Of course, all units are subjected to a final review. For this, among other things there are various instruments like Ozilloskope, Tesla Meter, LCR- bridge, microscopes and a helium leak tester.

There are 4 ESD workstations for the assembly of sensitive electronic components available. Furthermore, we offer through our flowboxes ISO Class 5, a particularly dust-free assembly.

Bonding of electronic components for clean room and optics, as well as the casting of special silicone seals are part of our standard work.

Our employees in the assembly area can trust in her experience and the optimum support from the development team.

Clean room assembly

According to individual customer requirements can be particularly sensitive assemblies and components assembled under clean room environment and are packed dust. To the assembled under clean room conditions Products include eg Components for electron microscopes, which are used in the TFT-LCD manufacturing and semiconductor industries.

We have clean rooms categories ISO 14644-1, Class 5 and Class 7 This corresponds to U.S. FED STD 209E Class 100 and 10,000.